Dust Extractors For Small Workshops Can Be Fun For Everyone

Table of ContentsThe Dust Extractors For Small Workshops PDFsSome Known Factual Statements About Dust Extractors For Small Workshops The 9-Second Trick For Dust Extractors For Small WorkshopsThe Dust Extractors For Small Workshops Diaries

The challenges for shop dust collection systems revolve around crystalline silica dust, carbon monoxide, as well as heat, which are toxic mixes. These variables make meeting air top quality standards hard as well as requiring. For that reason, when choosing a dirt control system for a shop, the first factor to consider is the ability of the device to withstand harsh and harmful work environment conditions.

Dirt collection systems for this type of procedure should be specifically designed to fit the kind of covering being applied. The purpose of the system is to control as well as minimize overspray and dust.

Though it would certainly appear likely to raise airflow and also motion, this sort of option might be inefficient as well as waste power. The design of the cubicle depends on the force of the air getting in the cell or cubicle. For the majority of systems, it is essential to have a minor vacuum cleaner in the booth to stay clear of feasible favorable stress.

The 10-Second Trick For Dust Extractors For Small Workshops

An additional approach is merely placing the make-up air link on the top of the cubicle. No matter the layout, it is crucial for the cleaning of the air to have cross air flow. Much like a cleanroom, air movement in a thermal spray cubicle can be either straight or downward, though the downward layout is best for dirt collection systems.

The pharmaceutical industry is an extremely managed sector with extensive and accurate regulations. Dust from pharmaceuticals is generated mostly throughout the production and also product packaging of items. Each step of creating a medication, which consists of granulating, drying, mixing, pushing, coating, and grinding, creates huge amounts of dirt that require to be gotten rid of.

Obstructing as well as managing this dissemination is the feature of the dirt control system. When developing a dirt control system for a pharmaceutical plant, the very first consideration is mapping the ventilation system to track the path of dirt, fumes, existing air movement patterns, as well as feasible transformative changes. Considering that numerous pharmaceutical dusts are flammable, the design of the air flow system is very important.

HEPA filters are typically found in pharmaceutical dirt control systems given that they are the most effective and dependable. Similar to a foundry system, they are mounted as an additional security to attain no emissions. Reusing generates a terrific offer of dirt as a natural outcome of diminishing products to their basic materials.

The smart Trick of Dust Extractors For Small Workshops That Nobody is Talking About

Dust comes from after materials are shredded, crushed, or have paint or lacquer removed. All recycling facilities are needed to follow air high quality standards. As click this link they function to meet top quality criteria and also control toxins, they have actually recognized that dust control is a major concern, leading to the broad use of dirt collection systems to mitigate and include the problem. dust extractors for small workshops.

When makers choose a dust control system, they are suggested by producers regarding the kind of system that would certainly best fit their needs since buying and setting up a dust control system is a significant investment. Particulate issue is available in a vast range of kinds, from silicon dirt to wood chips as well as sawdust.

The smart Trick of Dust Extractors For Small Workshops That Nobody is Talking About

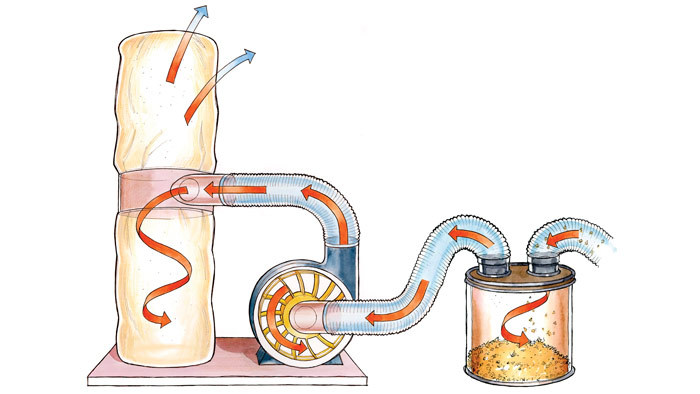

Textile filter bags in a cartridge system are the most efficient approach for collecting dust. Dirt collection systems are covered to include the dirt and also tidy the air.

Plastic Dust High-Density Polyethylene (HDPE) dirt is produced in the manufacturing of plastic panels when they are shaped as well as based on an edge trimmer, mill, or miter saw. Paper Dirt Among the a lot more common types of dust is paper dust, the adverse effects of the manufacturing of numerous sorts of paper.

With the intro of dust collection systems, workers are much safer click to read more and extra safeguarded. Sugar Sugar dirt is the byproduct of the production of sweet.

Rice Dust Rice dirt has really fine and also minute particles that collect during the production of rice-based products. A dust collection system is needed for the security and safety of employees.